-

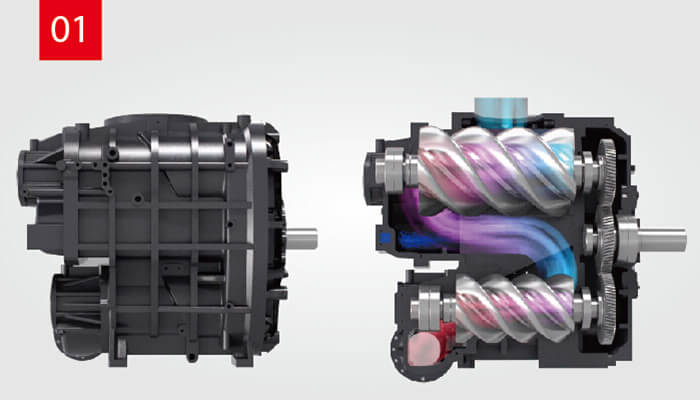

01Feature:

Two-stage compression air-end

Advantage:

Low compression ratio

Low temperature rising

Low air leakage

Benefit:

15% energy-saving -

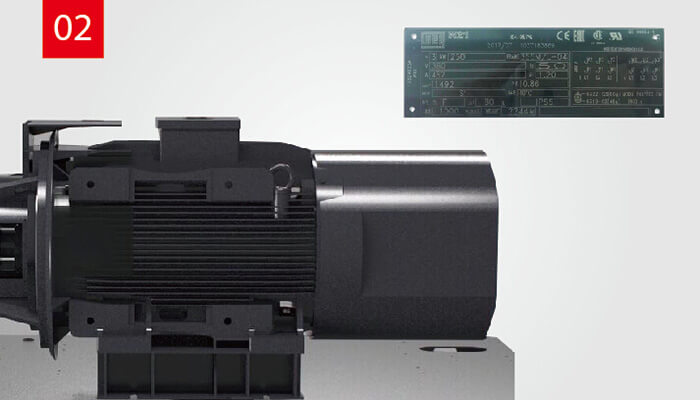

02Feature:

IE4 Permanent magnet motor /

Advantage:

Motor efficiency 97%

Benefit:

5% energy-saving -

03Feature:

2-VFD System

Advantage:

Constant pressure output to remove pressure fluctuation and off-load

Constant temperature output at 80~85℃

Low starting current to protect components

Benefit:

15% energy-saving -

04Feature:

Customized pressure system

Advantage:

Avoid excess pressure waste

Benefit:

7% energy-saving -

05Feature:

Seamless piping system

Advantage:

Smooth, rust-free, good appearance

Benefit:

No pressure loss -

06Feature:

Large oil system

Advantage:

Reduce internal pressure loss

Avoid oil leakage for safety

Benefit:

3% energy-saving -

07Feature:

Large cooler system

Advantage:

Centrifugal fan used for

good cooling effect

Benefit:

Allow ambient temperature at 52℃ -

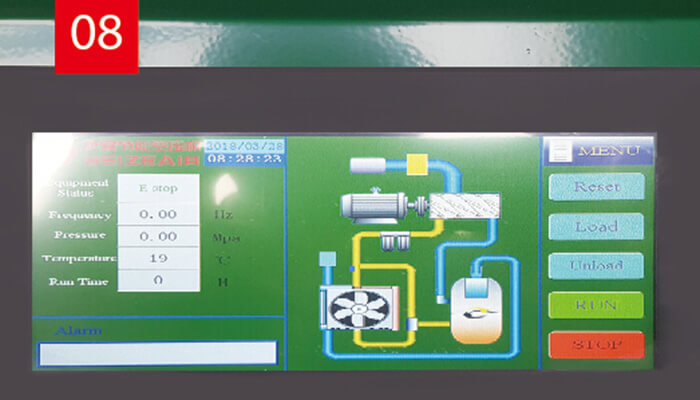

08Feature:

Intelligent control system

Advantage:

10 inch monitor to show all the data

Benefit:

Simple operation and trouble free -

09Feature:

Double filtering system

Advantage:

Remove impurity from air and ensure air cleanness

Benefit:

Longer life of air-end and lubrication oil -

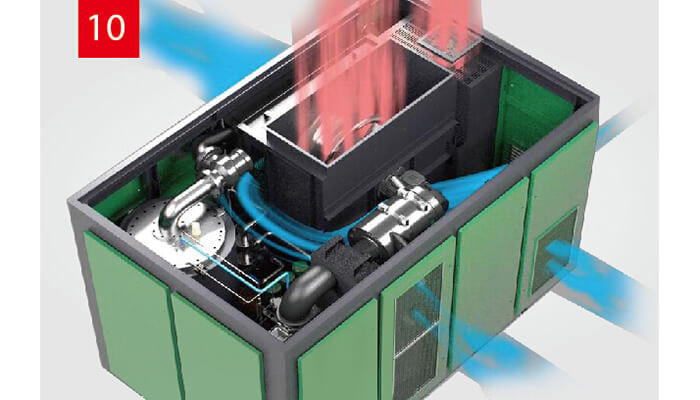

10Feature:

Air routing system

Advantage:

Cold air side suction and hot air top discharge

Benefit:

2% energy-saving

Seize air two stage air compressor can be more efficient and help save electric energy,these compressors are used for 4.5~12.5 bar pressure applications,with the development of industry ,compressors are very important for the manufacturers,processors and operators receive consistent,high-quality low cost air.

|

Model |

Maximum working pressure |

Capacity (FAD) |

Motor power |

Mode of driving |

Noise level |

Outlet pipe dia. |

Dimensions (mm) |

Weight |

|||||

|

bar |

psig |

m3/min |

cfm |

kw |

hp |

|

db |

inch |

L |

W |

H |

kg |

|

|

SVC-15A II |

4.5 |

65 |

1.0~3.9 |

35.3~137.7 |

15 |

20 |

Direct driving |

65 |

1 1/2 |

1500 |

900 |

1270 |

1200 |

|

5.5 |

80 |

0.9~3.5 |

31.8~123.6 |

||||||||||

|

6.5 |

94 |

0.8~3.2 |

28.2~113.0 |

||||||||||

|

7.5 |

109 |

0.7~3.0 |

24.7~105.9 |

||||||||||

|

8.5 |

123 |

0.7~2.9 |

24.7~102.4 |

||||||||||

|

10.5 |

152 |

0.6~2.4 |

21.2~84.7 |

||||||||||

|

12.5 |

181 |

0.5~2.0 |

17.7~70.6 |

||||||||||

|

SVC-18A II |

4.5 |

65 |

1.2~4.8 |

42.4~169.4 |

18.5 |

25 |

Direct driving |

65 |

1 1/2 |

1500 |

900 |

1270 |

1250 |

|

5.5 |

80 |

1.1~4.3 |

38.8~151.8 |

||||||||||

|

6.5 |

94 |

1.0~4.0 |

35.3~141.2 |

||||||||||

|

7.5 |

109 |

0.9~3.8 |

31.8~134.1 |

||||||||||

|

8.5 |

123 |

0.8~3.4 |

28.2~120.0 |

||||||||||

|

10.5 |

152 |

0.7~2.9 |

24.7~102.4 |

||||||||||

|

12.5 |

181 |

0.7~2.7 |

24.7~95.3 |

||||||||||

|

SVC-22A II |

4.5 |

65 |

1.6~6.4 |

56.5~225.9 |

22 |

30 |

Direct driving |

65 |

2 |

1650 |

1050 |

1370 |

1480 |

|

5.5 |

80 |

1.5~6.1 |

53.0~215.3 |

||||||||||

|

6.5 |

94 |

1.2~4.8 |

42.4~169.4 |

1 1/2 |

1500 |

900 |

1270 |

1350 |

|||||

|

7.5 |

109 |

1.1~4.5 |

38.8~158.9 |

||||||||||

|

8.5 |

123 |

1.1~4.3 |

38.8~151.8 |

||||||||||

|

10.5 |

152 |

0.8~3.4 |

28.2~120.0 |

||||||||||

|

12.5 |

181 |

0.7~2.9 |

24.7~102.4 |

||||||||||

|

SVC-30A II |

4.5 |

65 |

2.1~8.6 |

74.1~303.6 |

30 |

40 |

Direct driving |

68 |

2 |

1650 |

1050 |

1370 |

1550 |

|

5.5 |

80 |

1.9~7.7 |

67.1~271.8 |

||||||||||

|

6.5 |

94 |

1.8~7.0 |

63.5~247.1 |

||||||||||

|

7.5 |

109 |

1.6~6.8 |

56.5~240.0 |

||||||||||

|

8.5 |

123 |

1.5~6.2 |

53.0~218.9 |

||||||||||

|

10.5 |

152 |

1.2~4.7 |

42.4~165.9 |

1 1/2 |

1500 |

900 |

1270 |

1450 |

|||||

|

12.5 |

181 |

1.1~4.3 |

38.8~151.8 |

||||||||||

|

SVC-37A II |

4.5 |

65 |

2.6~10.3 |

91.8~363.6 |

37 |

50 |

Direct driving |

68 |

2 |

1800 |

1150 |

1390 |

1750 |

|

5.5 |

80 |

2.4~9.5 |

84.7~335.4 |

||||||||||

|

|

6.5 |

94 |

2.2~8.7 |

77.7~307.1 |

|

|

|

|

|

1650 |

1050 |

1370 |

1600 |

|

7.5 |

109 |

1.9~7.5 |

67.1~264.8 |

||||||||||

|

8.5 |

123 |

1.8~7.4 |

63.5~261.2 |

||||||||||

|

10.5 |

152 |

1.5~6.0 |

53.0~211.8 |

||||||||||

|

12.5 |

181 |

1.4~5.6 |

49.4~197.7 |

||||||||||

|

SVC-45A II |

4.5 |

65 |

3.3~13.1 |

116.5~462.4 |

45 |

60 |

Direct driving |

68 |

DN65 |

2100 |

1300 |

1680 |

2000 |

|

5.5 |

80 |

2.9~11.5 |

102.4~406.0 |

2 |

1800 |

1150 |

1390 |

1800 |

|||||

|

6.5 |

94 |

2.4~10.5 |

84.7~370.7 |

||||||||||

|

7.5 |

109 |

2.3~10.0 |

81.2~353.0 |

||||||||||

|

8.5 |

123 |

2.2~8.6 |

77.7~303.6 |

1650 |

1050 |

1370 |

1650 |

||||||

|

10.5 |

152 |

1.9~7.5 |

67.1~264.8 |

||||||||||

|

12.5 |

181 |

1.6~6.4 |

56.5~225.9 |

||||||||||

|

SVC-55A/W II |

4.5 |

65 |

3.9~15.5 |

137.7~547.2 |

55 |

75 |

Direct driving |

70 |

DN65 |

2100 |

1300 |

1680 |

2300 |

|

5.5 |

80 |

3.4~14.5 |

120.0~511.9 |

||||||||||

|

6.5 |

94 |

3.2~13.3 |

113.0~469.5 |

||||||||||

|

7.5 |

109 |

3.0~13.1 |

105.9~462.4 |

||||||||||

|

8.5 |

123 |

2.8~12.3 |

98.8~434.2 |

||||||||||

|

10.5 |

152 |

2.3~10.1 |

81.2~356.5 |

2 |

1800 |

1150 |

1390 |

1900 |

|||||

|

12.5 |

181 |

1.9~8.0 |

67.1~282.4 |

||||||||||

|

SVC-75A/W II |

4.5 |

65 |

4.2~20.7 |

148.3~730.7 |

75 |

100 |

Direct driving |

70 |

DN80 |

2740 |

1740 |

1820 |

2800 |

|

5.5 |

80 |

4.8~19.0 |

169.4~670.7 |

||||||||||

|

6.5 |

94 |

4.5~17.0 |

158.9~600.1 |

DN65 |

2100 |

1300 |

1680 |

2400 |

|||||

|

7.5 |

109 |

4.2~16.6 |

148.3~586.0 |

||||||||||

|

8.5 |

123 |

3.8~15.5 |

134.1~547.2 |

||||||||||

|

10.5 |

152 |

3.4~13.6 |

120.0~480.1 |

||||||||||

|

12.5 |

181 |

2.9~11.5 |

102.4~406.0 |

2 |

1800 |

1150 |

1390 |

1900 |

|||||

|

SVC-90A/W II |

4.5 |

65 |

6.4~25.6 |

225.9~903.7 |

90 |

120 |

Direct driving |

73 |

DN100 |

2850 |

1850 |

1950 |

3800 |

|

5.5 |

80 |

5.9~23.6 |

208.3~833.1 |

DN80 |

2740 |

1740 |

1820 |

3000 |

|||||

|

6.5 |

94 |

5.6~20.8 |

197.7~734.3 |

||||||||||

|

7.5 |

109 |

5.3~20.6 |

187.1~727.2 |

||||||||||

|

8.5 |

123 |

4.9~20.0 |

173.0~706.0 |

||||||||||

|

10.5 |

152 |

4.1~16.3 |

144.7~575.4 |

DN65 |

2100 |

1300 |

1680 |

2400 |

|||||

|

12.5 |

181 |

3.9~15.3 |

137.7~540.1 |

||||||||||

|

SVC-110A/W II |

4.5 |

65 |

7.7~30.0 |

271.8~1059.0 |

110 |

150 |

Direct driving |

73 |

DN100 |

2850 |

1850 |

1950 |

4000 |

|

5.5 |

80 |

7.2~28.2 |

254.2~995.5 |

||||||||||

|

6.5 |

94 |

6.7~26.0 |

236.5~917.8 |

||||||||||

|

7.5 |

109 |

6.1~24.5 |

215.3~864.9 |

DN80 |

2740 |

1740 |

1820 |

3200 |

|||||

|

8.5 |

123 |

5.8~23.0 |

204.7~811.9 |

||||||||||

|

10.5 |

152 |

5.1~20.1 |

180.0~709.5 |

||||||||||

|

12.5 |

181 |

4.4~17.3 |

155.3~610.7 |

|

SVC-120A/W II |

4.5 |

65 |

8.8~35.0 |

310.6~1235.5 |

120 |

160 |

Direct driving |

73 |

DN125 |

2970 |

1920 |

2060 |

4800 |

|

5.5 |

80 |

7.9~30.0 |

278.9~1059.0 |

DN100 |

2850 |

1850 |

1950 |

4300 |

|||||

|

6.5 |

94 |

7.2~28.2 |

254.2~995.5 |

||||||||||

|

7.5 |

109 |

6.5~26.0 |

229.5~917.8 |

||||||||||

|

8.5 |

123 |

6.1~24.8 |

215.3~875.4 |

||||||||||

|

10.5 |

152 |

5.6~22.9 |

197.7~808.4 |

DN80 |

2740 |

1740 |

1820 |

3400 |

|||||

|

12.5 |

181 |

4.7~19.2 |

165.9~677.8 |

||||||||||

|

SVC-132A/W II |

4.5 |

65 |

9.6~38.3 |

338.9~1352.0 |

132 |

175 |

Direct driving |

73 |

DN125 |

2970 |

1920 |

2060 |

5000 |

|

5.5 |

80 |

8.8~35.0 |

310.6~1235.5 |

||||||||||

|

6.5 |

94 |

7.8~33.0 |

275.3~1164.9 |

||||||||||

|

7.5 |

109 |

7.2~30.0 |

254.2~1059.0 |

DN100 |

2850 |

1850 |

1950 |

4500 |

|||||

|

8.5 |

123 |

6.9~28.0 |

243.6~988.4 |

||||||||||

|

10.5 |

152 |

6.1~24.1 |

215.3~850.7 |

DN80 |

2740 |

1740 |

1820 |

4000 |

|||||

|

12.5 |

181 |

5.4~21.3 |

190.6~751.9 |

||||||||||

|

SVC-150A/W II |

4.5 |

65 |

10.5~42.0 |

370.7~1482.6 |

150 |

200 |

Direct driving |

78 |

DN125 |

3300 |

2050 |

2150 |

5300 |

|

5.5 |

80 |

9.6~38.3 |

338.9~1352.0 |

||||||||||

|

6.5 |

94 |

8.8~35.0 |

310.6~1235.5 |

||||||||||

|

7.5 |

109 |

8.1~33.0 |

285.9~1164.9 |

||||||||||

|

8.5 |

123 |

7.4~30.0 |

261.2~1059.0 |

DN100 |

2850 |

1850 |

1950 |

4800 |

|||||

|

10.5 |

152 |

6.5~28.0 |

229.5~988.4 |

||||||||||

|

12.5 |

181 |

6.1~24.3 |

215.3~857.8 |

||||||||||

|

SVC-160A/W II |

4.5 |

65 |

11.0~44.0 |

388.3~1553.2 |

160 |

215 |

Direct driving |

78 |

DN125 |

3300 |

2050 |

2150 |

5800 |

|

5.5 |

80 |

10.5~42.0 |

370.7~1482.6 |

||||||||||

|

6.5 |

94 |

9.6~38.3 |

338.9~1352.0 |

||||||||||

|

7.5 |

109 |

8.8~35.0 |

310.6~1235.5 |

||||||||||

|

8.5 |

123 |

8.1~33.0 |

285.9~1164.9 |

||||||||||

|

10.5 |

152 |

7.7~30.0 |

271.8~1059.0 |

DN100 |

2850 |

1850 |

1950 |

5000 |

|||||

|

12.5 |

181 |

6.5~26.3 |

229.5~928.4 |

||||||||||

|

SVC-185A/W II |

4.5 |

65 |

12.5~50.0 |

441.3~1765.0 |

185 |

250 |

Direct driving |

78 |

DN150 |

3650 |

2250 |

2300 |

7000 |

|

5.5 |

80 |

11.5~46.0 |

406.0~1623.8 |

||||||||||

|

6.5 |

94 |

11.0~44.0 |

388.3~1553.2 |

DN125 |

3300 |

2050 |

2150 |

6000 |

|||||

|

7.5 |

109 |

10.7~42.0 |

377.7~1482.6 |

||||||||||

|

8.5 |

123 |

10.3~40.0 |

363.6~1412.0 |

||||||||||

|

10.5 |

152 |

8.8~35.5 |

310.6~1253.2 |

||||||||||

|

12.5 |

181 |

7.5~32.4 |

264.8~1143.7 |